| THE PROCESSES

Always

up-to date.

We settle for nothing but the best.

TECHNOLOGY

_

THE BEST

MACHINERY

ON THE MARKET

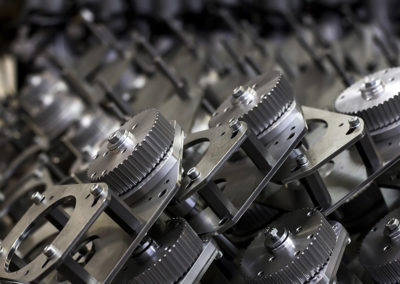

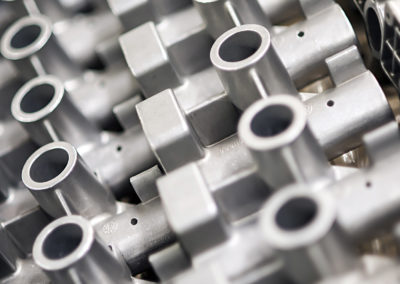

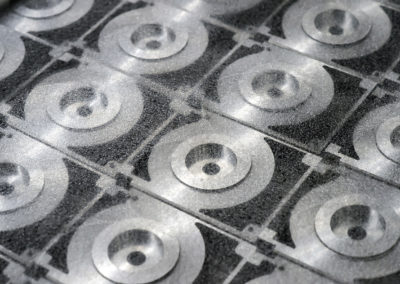

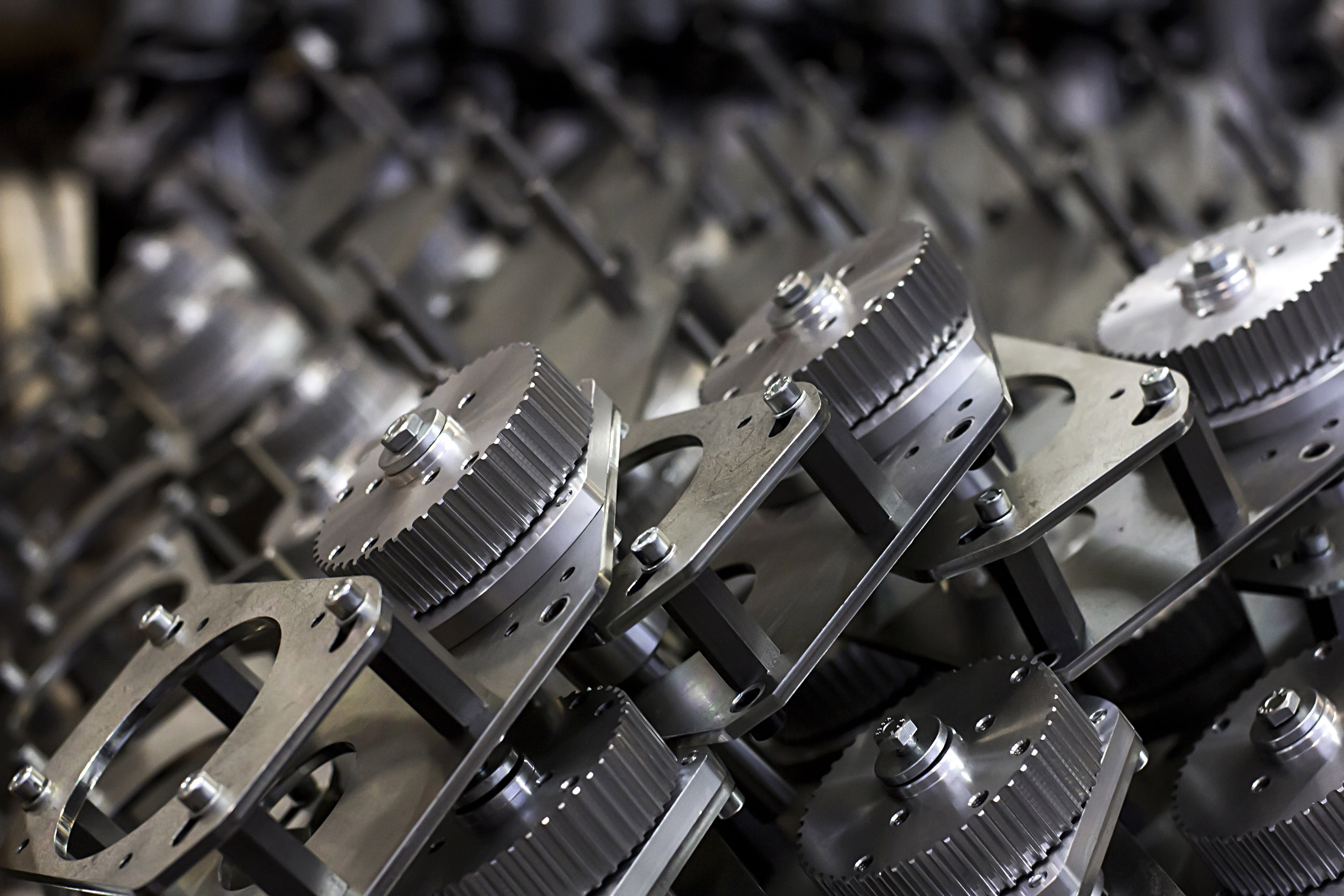

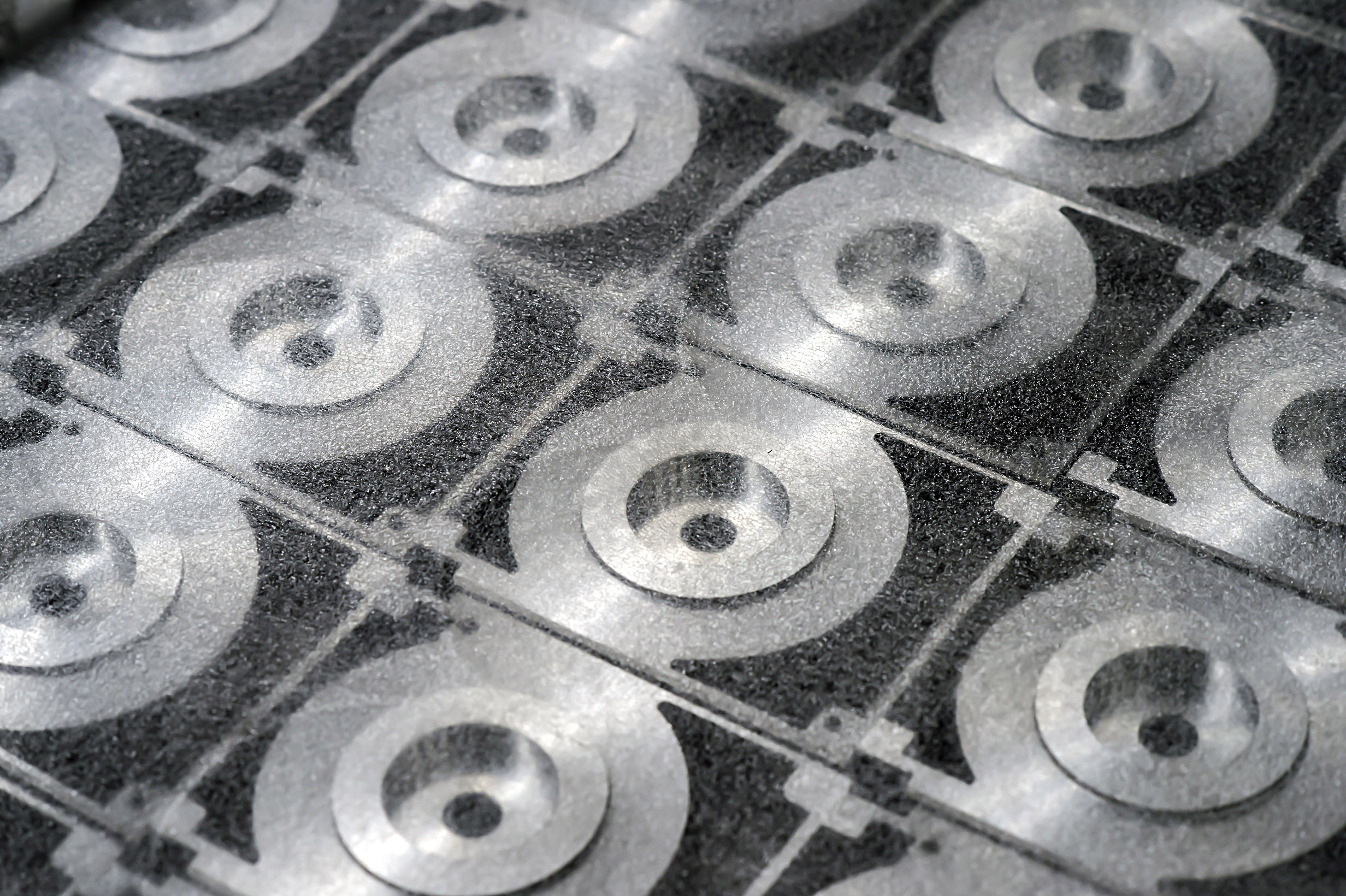

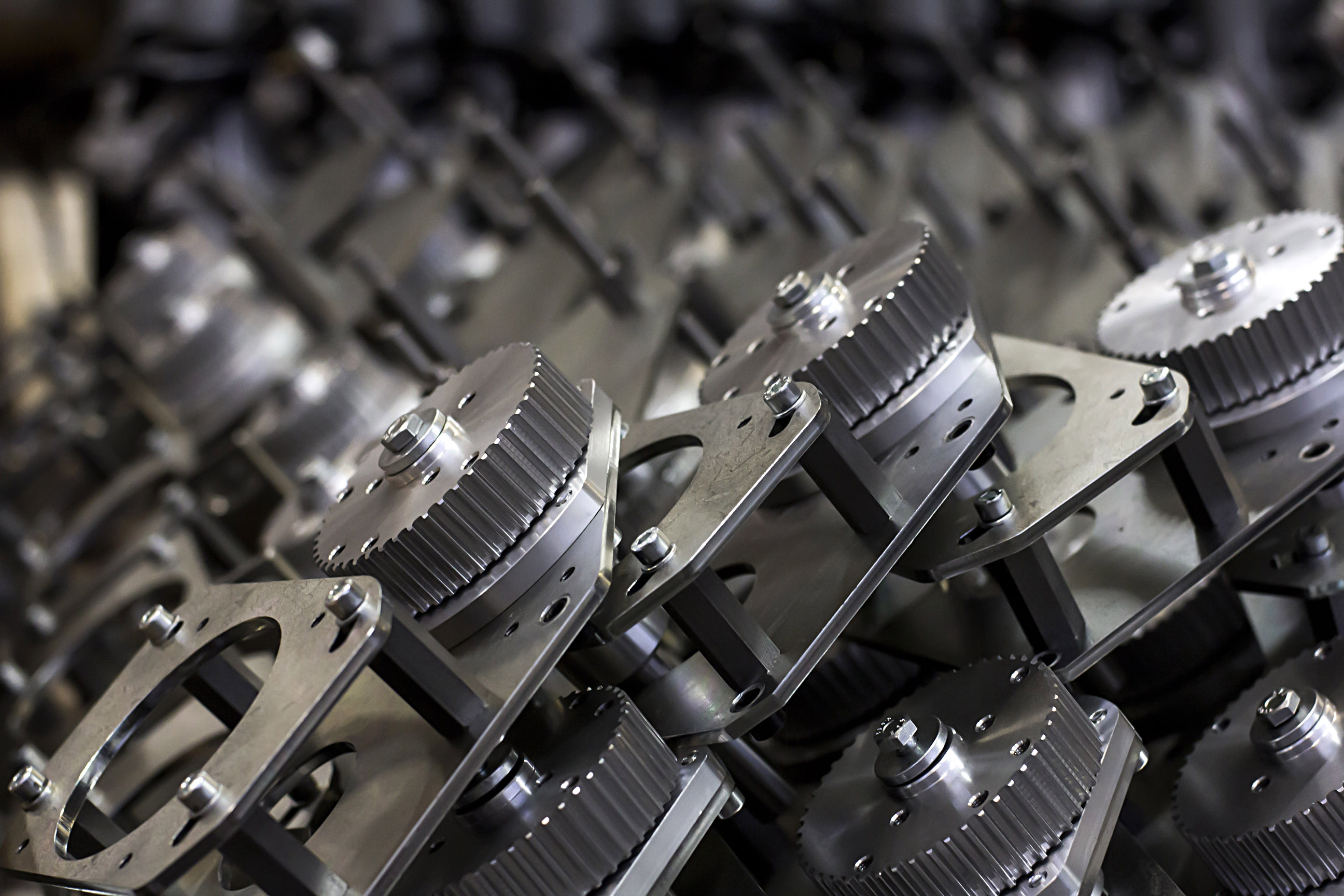

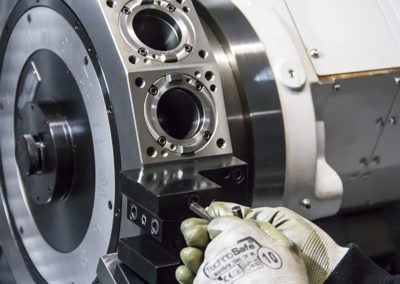

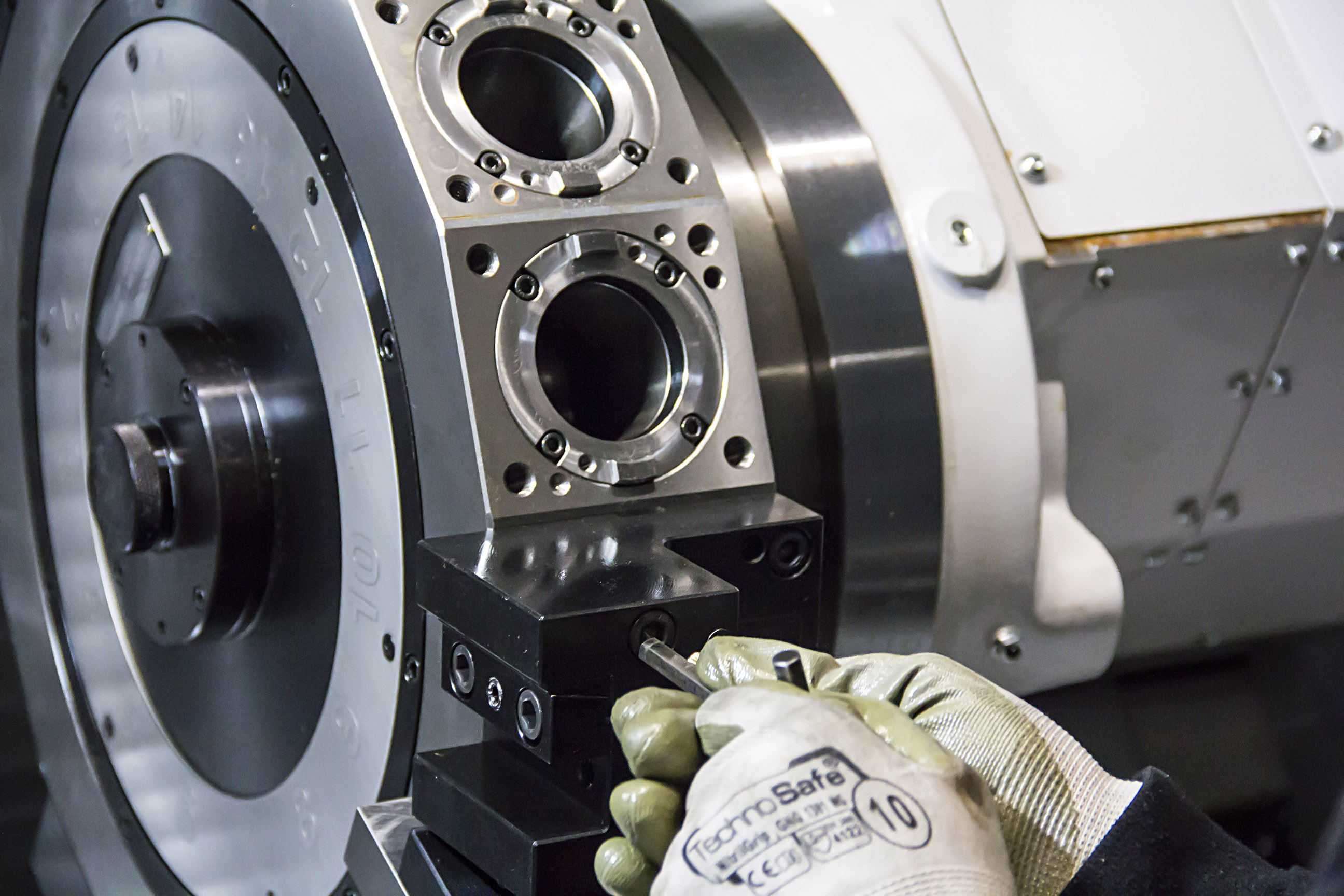

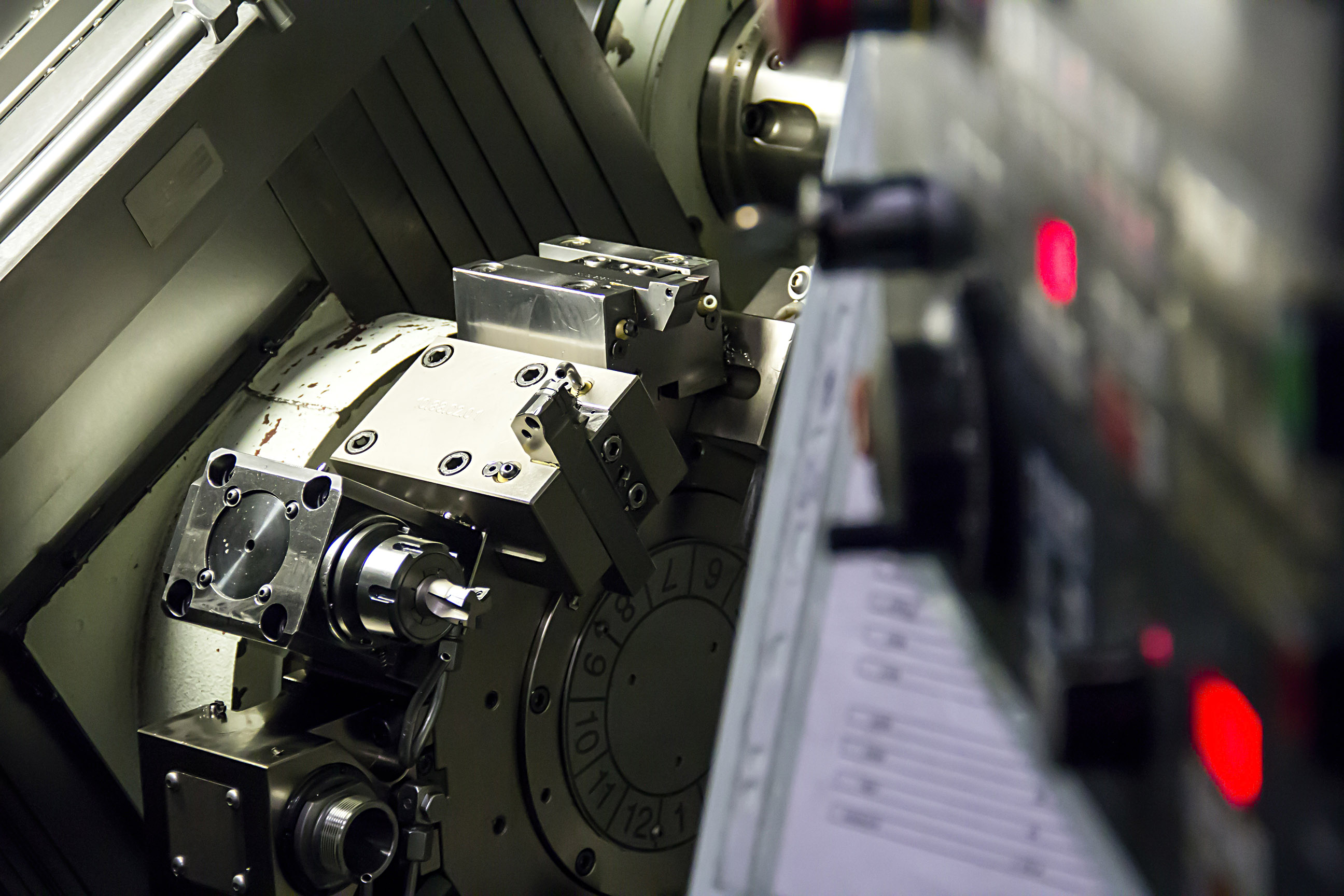

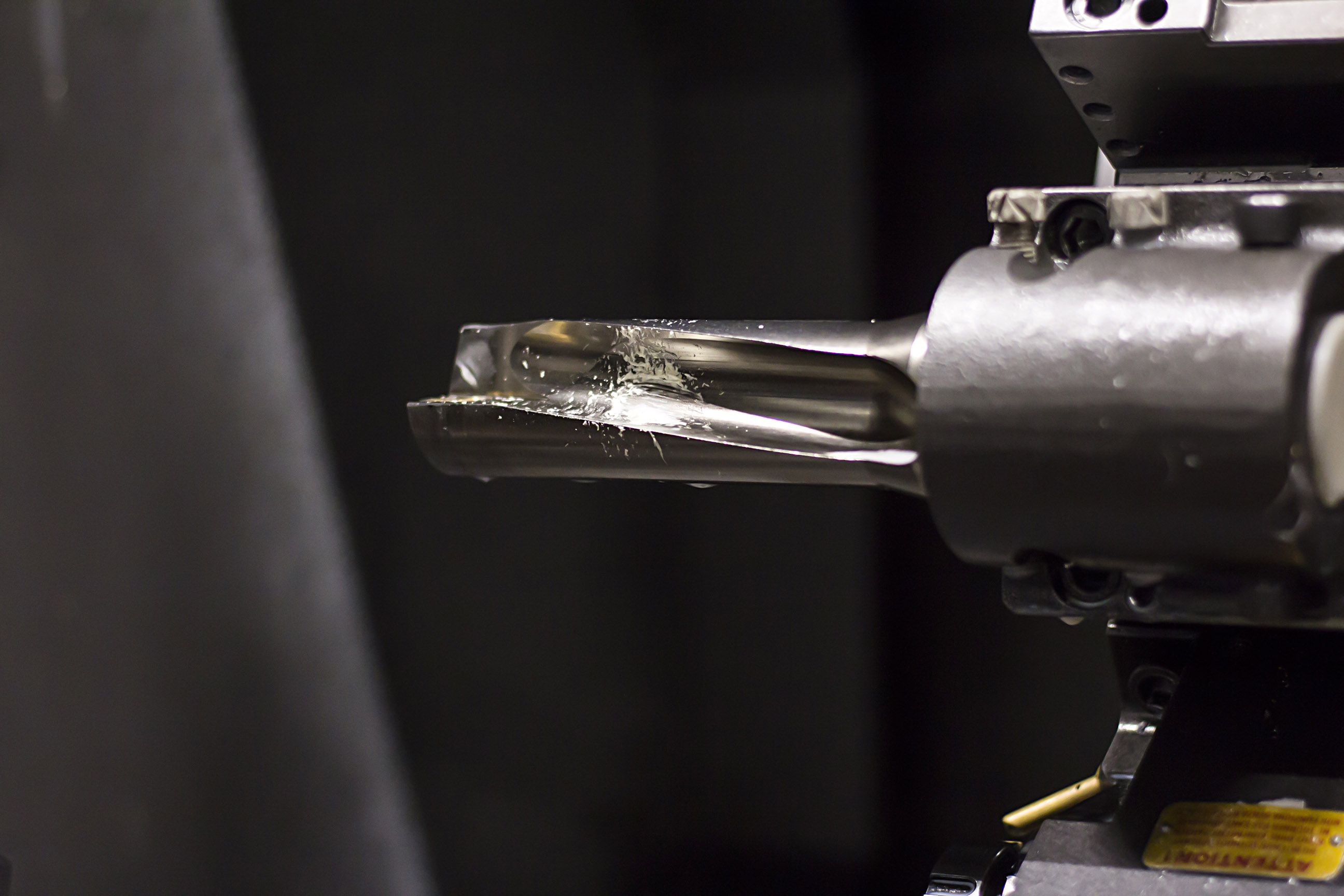

LMP is specialized in mechanical precision processing (turning, milling, broaching, toothing, grinding) using numerical control machinery, providing workpiece based on a technical drawing or on a sample.

![]() Milling

Milling

VERTICAL WORK CENTER MV-40

MORI SEIKI

1993

UT.TIPO BT40 CON 4°AX

VERTICAL WORK CENTER SPEEDO 700

BROTHER

2014

UTENSILI BT30 CON TAVOLA GIREVOLE ALTA VELOCITA’

HORIZONTAL WORK CENTER SH-500

MORI SEIKI

1999

UT.TIPO BT40 CAMBIO PALLET DA 500X500

VERTICAL WORK CENTER MMV-165

EMCO-FAMUP

2007

UT.TIPO BT40 LAV. IN PENDOLARE CON 4°ASSE

HORIZONTAL WORK CENTER SH-500

MORI SEIKI

2001

UT.TIPO BT40 CAMBIO PALLET DA 500X500

WORK CENTER OKK HMC 500

OKK

2017

UT.TIPO BT40 CAMBIO PALLET DA 500X500

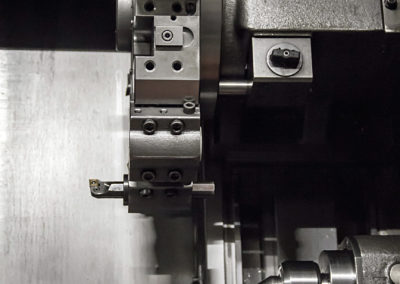

![]() Turning and secondary operation machines

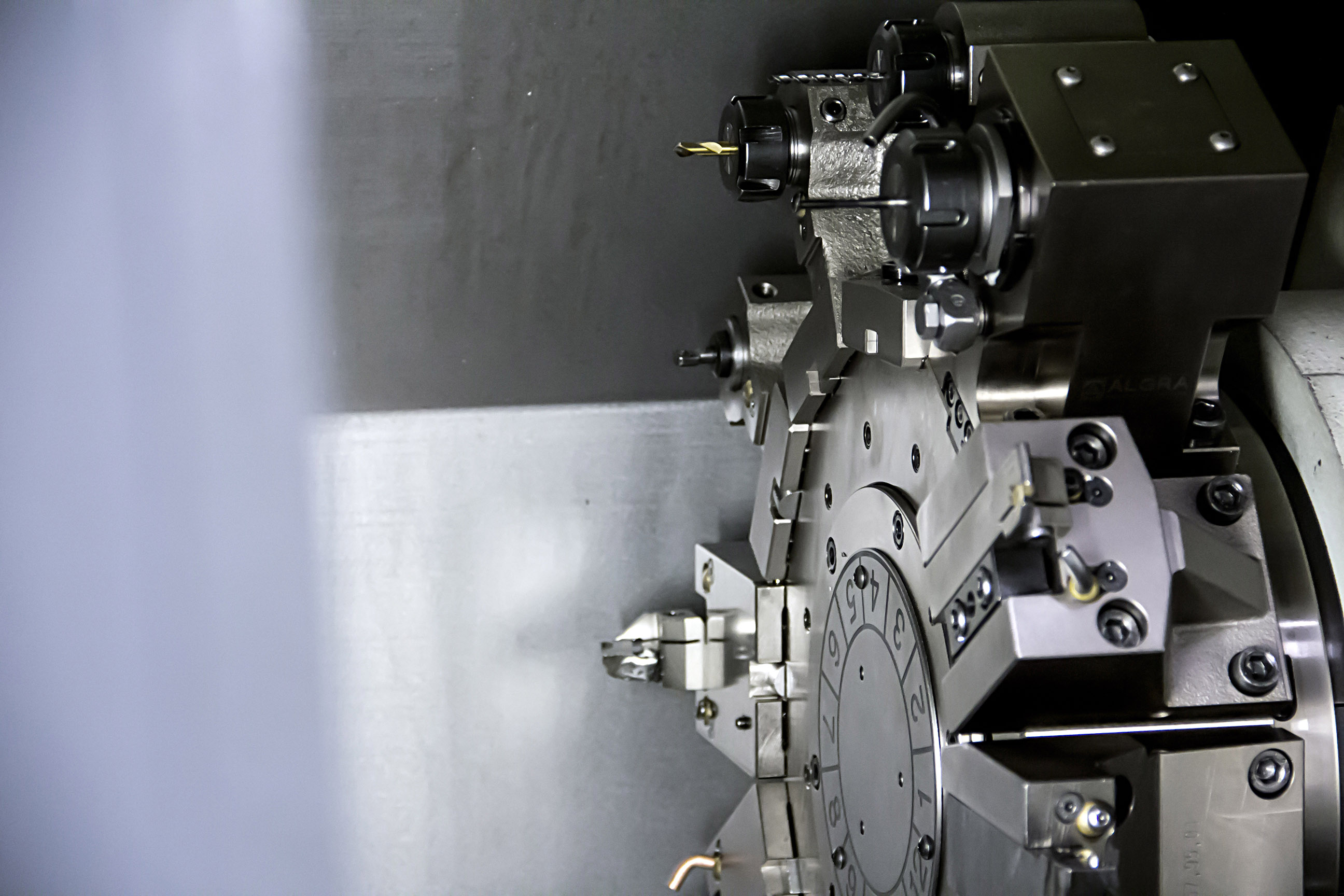

Turning and secondary operation machines

LATHE CNC AL-2

MORI SEIKI

1986

Ø TORNIBILE 250MM PASS. BARRA 42

LATHE CNC SL-25 B 1

MORI SEIKI

1995

Ø TORNIBILE 350MM PASS. BARRA 76

LATHE CNC SL-25 B 2

MORI SEIKI

1995

Ø TORNIBILE 350MM PASS. BARRA 76

LATHE CNC HS-21

HAWACHEON

1995

Ø TORNIBILE 250MM PASS. BARRA 52

LATHE CNC SL250B/500 1

MORI SEIKI

1997

Ø TORNIBILE 390MM PASS. BARRA 76

LATHE CNC SL250B/500 2

MORI SEIKI

1997

Ø TORNIBILE 390MM PASS. BARRA 76

LATHE CNC NL-2000

MORI SEIKI

2004

PASS. BARRA 65 UT. MOTORIZZATI 2 TESTE CON CARICATORE AUTOMATICO A PORTALE

LATHE CNC NL-2500 1

MORI SEIKI

2006

PASS. BARRA 76 UT. MOTORIZZATI CON ASSE Y

LATHE CNC NL-2500 2

MORI SEIKI

2006

PASS. BARRA 76 UT. MOTORIZZATI CON ASSE Y

LATHE CNC B-545 YS

BIGLIA

2008

BIMANDRINO PASS. BARRA 46 UT. MOTORIZZATI CON ASSE Y

LATHE TS4000 Y

TAKISAWA JAPAN

2017

PASSAGGIO BARRA 80 CON MOTORIZZATI E ASSE Y

LATHE TT-2600

TAKISAWA JAPAN

2016

TORNIO BIMANDRINO FRONTALE CON CARICATORE DI PEZZI IN AUTOMATICO

TAKISAWA JAPAN 2016

TAKISAWA JAPAN

2018

PASSAGGIO BARRA 80 CON MOTORIZZATI E ASSE Y

![]() By turned bar

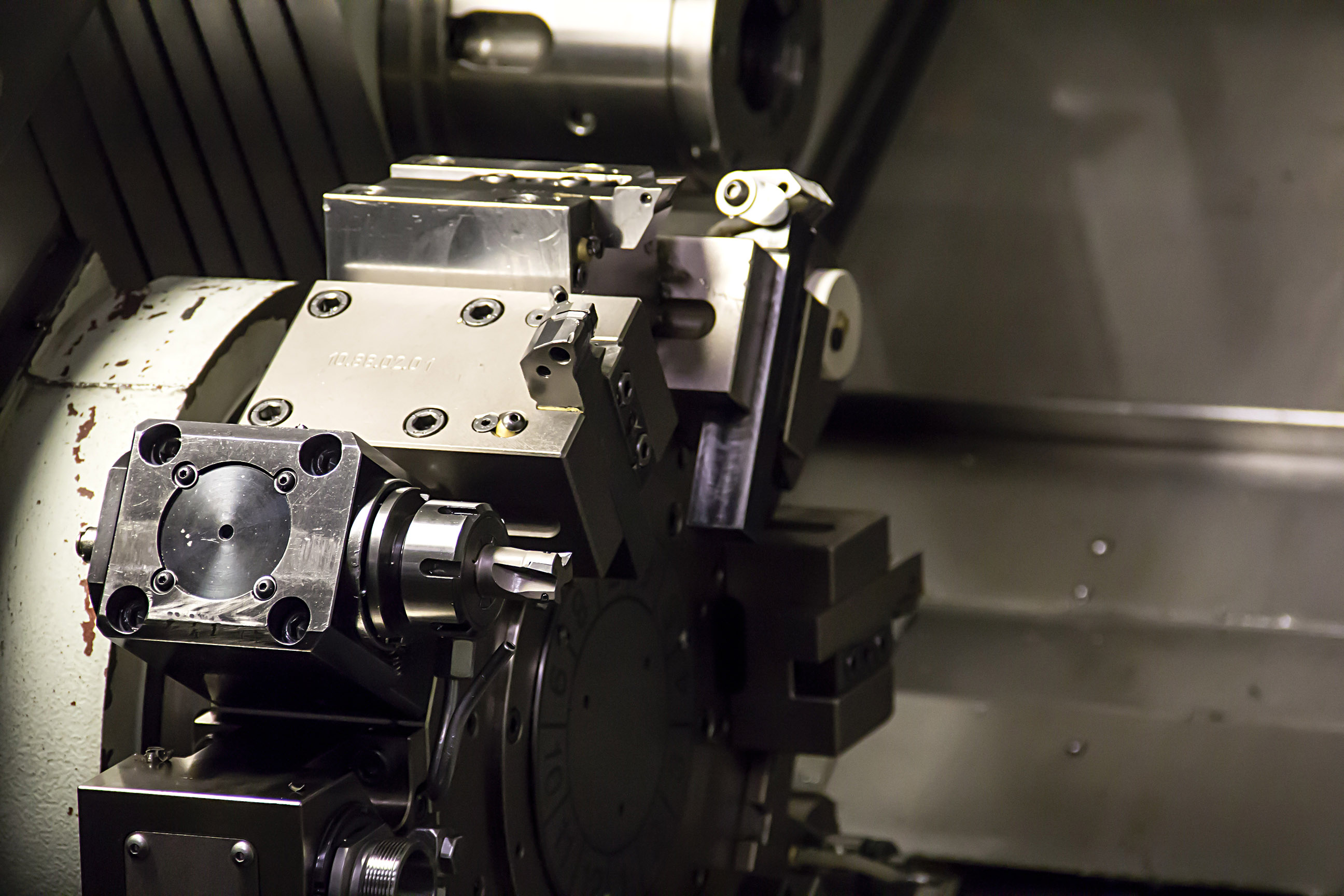

By turned bar

LATHE CNC WY 250L

NAKAMURA TOME

2014

PASS. BARRA 70 2 ASSI Y UT. MOTORIZZATI 2 TESTE 2 TORRETTE CON CARICATORE DI BARRE

LATHE CNC B565 YS

BIGLIA

2012

PASS. BARRA 65 ASSE Y UT. MOTORIZZATI 2 TESTE 2 TORRETTE CON CARICATORE DI BARRE LNS

LATHE CNC MURATA MT20

MURATA

2011

LATHE CNC SL-150S

MORI SEIKI

1996

DIA. TORNIBILE 184MM DOPPIO MANDRINO CON CARICATORE LNS PASSAGGIO BARRA MAX 45

![]() Traditional

Traditional

machinery

| BASIC LATHE 225 |

| BROCCIA BVM1000 |

| AUTOMATIC BAND SAWING AM 270 |

| AUTOMATIC BAND SAWING BTM 450 HFA |

| BAND SAWING KASTO HBA 420 CNC |

| AUTOMATIC BAND SAWING 170 |

| TOOTHING 0 |

| TOOTHING 251 |

| TOOTHING RS00 |

| RETTIFICA HTG 600 |

| PORE LAPPING MBB-1660 |

| AFFILATRICE SAACKE |

| RETTIFICA SENZA CENTRI |

| TRAPANO FERSA TCS VR DA |

| TRAPANO MASCHIATRICE IMM118 |

| TRAPANO MASCHIATRICE RAG 20/22 |

| TRAPANO MASCHIATRICE F22 |

| TRAPANO MASCHIATRICE BRAVA |

| TRAPANO MASCHIATRICE A3 |

Services

_

TO RESPOND AND SATISFY RAPIDLY TO CUSTOMER REQUESTS

LMP for all the processes offers a range of services tailored to the client’s necessity.

Specifically, we provide:

![]() Services

Services

INTERIOR

GALVANIZING TREATMENTS

The galvanisation is an industrial technique that allow to cover a non-precious metal with a thin layer of more precious or noble metal or passivablethrough the electrolytic deposition. This treatment assures the protection of the metals from the corrosion, but also for decorative purposes. For example, thanks to the galvanisation is possible to coat copper with silver or steel with zinc, tin, nickel and chromium.

HEAT TREATMENTS

For heat treatment we intend a thermal heating cycle, performed under predetermined standard condictions and temperatures, followed by coolings with the aim for the metal or the metal alloy, (usually steel) to assume those crystalline structures that confer them specific mechanical and/or technological characteristics. In this transformation, the cooling and heating speeds have crucial role. The speed affects the transition temperatures (generally different from the state diagrams), but also the nature and structure of the metal, becoming metastable alloys (like the martensite in the steel) absent in the state diagram.

PAINTING

• LIQUID PAINTING

The paint is applied on the metal in order to protect it from the outdoor weathering exposure and from the corrosion too. Before the application of the spray painting, the metal is subjected to the preliminary sandblasting, that removes, if present, rust residuals and calamine from the surface. There are various excellent spray paint techniques, which differ according to the result sought. For example the acrylic paint (named airless painting) has a low concentration of liquid, in this way the emission to air of volatile substances is minimum.

• POWDER PAINTING

The powder painting is more complex than the spray one. Whit this technique is possible to coat -using an organic film-the metallic surfaces in order to protect them from the outdoor weathering exposure and from the corrosion too.

The powder painting requires the use of highly specialised installations, to name a few: a workpieces washing system, an overhead conveyor belt where to hang the pieces ready for the paint, a polymerization oven and cabin with electrostatic spray guns.

The surface is treated and covered with an electrostatic charged powder painting composed of resins. Exploiting this electrostatic charge, the powder perfectly adhere to the surface. The next step is putting the object inside an oven where the paint melts and polymerise in a a single layer.

The powder painting allows to achieve an excellent adhesion between the paint and the surface, with a long lasting resistence to the outdoors corrosive agents. This great results are only possible after a proper and accurate treatment of the surface. If not, after the painting, some bubbles or peeling can appear on the workpiece, compromising its ultimate output.

ANODIZING

The anodizing (also known as anodic oxidation) is a not spontaneous electrochemical process, during which a protective oxide layer develops on the metal, protecting it from corrosion. The anodizing is commonly used on aluminium. The treated surface has a chemical transformation: the metal reacts with the oxygen developed during the electrodeposition, forming aluminium oxide or alumina. Similar procedures are disposable also on titanium, zinc, magnesium, niobium, zirconium, hafnium and tantalum.

EXTERNAL

INTERNAL ASSEMBLY DEPARTMENT

Our internal department allow us to personally prepare and delivery the components already assembled.

MARKING POINTS AND TRACEABILITY

Marking by Micro-Percussion creates an incision without removing part of the material and is made on all the materials, from plastics to hard steels. This will be the proof of traceability on every single piece.

MATERIALS

_

EACH PRODUCT,

ITS MATERIAL

LMP operates on many product sectors thanks to the variety of materials used.

The materials used in our supply chain are:

![]() Materials

Materials

| ALL TYPES OF STEEL |

| STAINLESS STEEL |

| CAST IRON |

| BRASS |

| BRONZE |

| ALUMINIUM |

| PLASTICS |

| FUSIONS OF ALUMINIUM AND CAST IRON |

Our strong points

Shipments

We deliver the product straight to your Company in 5 working days.

Timing

Our manufactures always meet the customer’s deadlines.

Packaging

The finished product is carefully packaged before the shipment.

The respect for the natural environment

The respect for the natural environment will assure us a better future.

I nostri punti di forza

Shipments

We deliver the product straight to your Company in 5 working days.

Timing

Our manufactures always meet the customer’s deadlines.

Packaging

The finished product is carefully packaged before the shipment.

The respect for the natural environment

The respect for the natural environment will assure us a better future.

The processes

Machinery

ALWAYS AT YOUR DISPOSAL

Customer service

Email info@lmp-aviano.it

Phone 0434 652394

Opening hours From Monday to Friday 8.00/ 6.00pm

ADDRESS

L.M.P. Srl Lavorazioni meccaniche di precisione

Via Monte Tremol, 17

33081 Zona Industriale PN

C.F. e P.IVA. 00381290931

tel +39 0434 652394

2018 © L.M.P. srl Lavorazioni Meccaniche di Precisione Aviano (PN) - p.iva 00381290931